Corum Golden Bridge Clock Table

No, I didn’t get that headline wrong. We are not talking about a table clock. Well, we are, but not in the traditional sense of the word. Typically, a table clock is a clock that sits on a table. The new Corum Golden Bridge Clock is, in itself, a coffee table — a work of sculptured art — that is also a fully functioning clock.

Almost since its inception in 1955, Corum has been all about daring creativity. This is the brand that sliced a coin in half and housed a movement inside. This is the brand that purchased Vincent Calabrese’s innovative in-line movement and created the iconic Golden Bridge line of watches. It is the brand that released the beloved Bubble with cult-like following and the much-coveted Admiral. Now, this brand branches out into new territory with its clock table.

The artist, Pedro Costa, sculpts the table in the likeness of the Golden Bridge case — just 20 times larger.

Made to order, it is a fully functional clock that is 100 percent hand made as an exact replica – right down to the engraving — of the Golden Bridge watch but is in the form of a coffee table. Weighing in at just about 220 pounds, the Golden Bridge Clock Table takes Corum’s clock and table-making partners at least four months to build — translating to the creation of just three to five pieces per year.

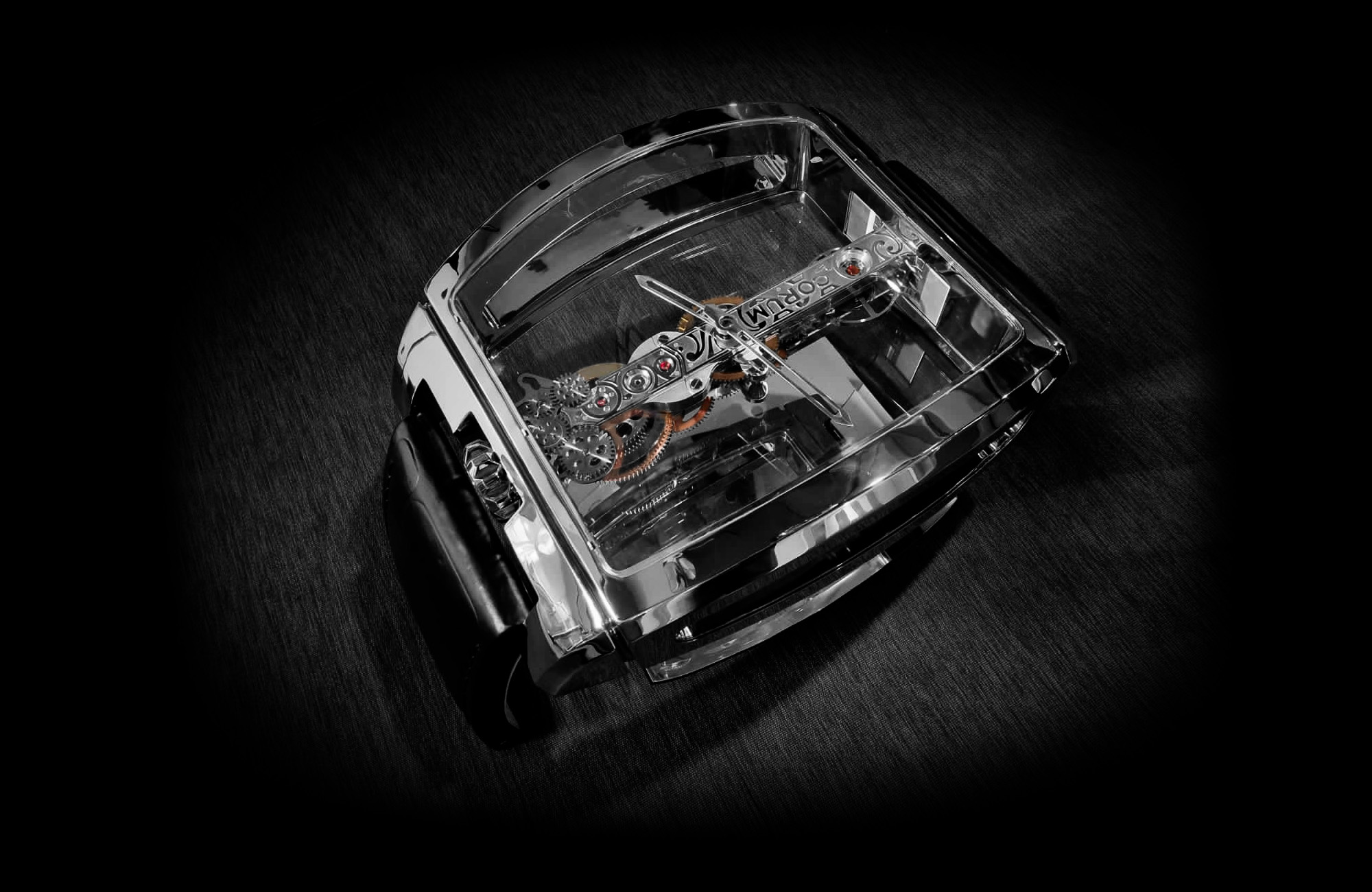

The clock is meant to reflect the Golden Bridge watch, but at 20 times the actual size and, like the watch, with every part visible via a transparent top. For the making of the clock case – or table, if you will – Corum turned to metal artisan Pedro Costa of Costa Design. Costa turns sheets of metal like stainless steel and aluminum into art, replicating a watch collector’s favorite piece in clock table format.

It takes approximately four months to create one clock, including the case and the movement.

For each table, Costa Design makes its own tools and then goes into an intensive process that includes design, 3D modeling, printing and more to understand volume and proportions. Then, once started, each clock table is individually forged, bent, carved, welded, lathed and polished to perfection. As such it takes about three to four months or more to complete one table. After that, the table and the clock movement are put together – breathing life into the work of art.

The Movement of the Corum Golden Bridge Clock Table

The made-to-order clock, which retails for about $125,000, houses a fully working mechanism made by Sinclair Harding in the United Kingdom. It is housed in a stainless steel, aluminum, iron, acrylic and glass case that forms the table.

Each Corum Golden Bridge Clock Table retails for about $125,000, and just a handful will be made annually.

The hands of the clock are controlled by a stepper motor and an in-house designed and manufactured precision gearbox with a 108-tooth anti-backlash gear to minimize noise and improve accuracy. Then, “by pulling a manual hand setting crown hidden inside the watch case crown, the hands can be adjusted clockwise or anti-clockwise via a contrate pinion and wheel arrangement.”

All of the movement parts are high-grade brass, stainless steel, or aircraft-grade aluminum finished in nickel, gold or platinum plating to emulate the movement of the Golden Bridge watch. The parts are finished by hand with techniques that emulate the original watch movements, including mirror hand-polishing, graining and sandblasting. The movement, consisting of 295 parts (including 156 unique components and 25 sub-assemblies) weighs almost 35 pounds all by itself. Currently, the movement inside the clock is created by Sinclair Harding in England and is powered by a high-precision stepper motor and boasts a rechargeable battery that can offer 144 hours of power reserve. According to Corum, in the future, the movement will be fully mechanical with seven days of power reserve and will be made in Europe.

The Corum Golden Bridge Clock Table is created to replicate its legendary Golden Bridge watch.

In the meantime, Costa turned to Sinclair Harding led by Robert Bray for the initial clock movements. Bray, an engineer for decades, with experience in manufacturing gears and gear boxes for the aerospace industry, took over the company in 1995 when it was floundering and set his sights and skills on creating clocks. Determined to be totally independent and to make every part for every clock himself (a goal he accomplished by 2017), Bray was the lead on creating the movement for the Corum Golden Bridge Clock Table. He and his team work together to build each movement, complete with polishing, engraving, bluing of screws and more.

According to Boon Chong Soon, Corum’s Vice President, “We are being very exclusive with the table. It isn’t an item for everyone. For us, it is about taking the notion of a table clock much further and surprising our customers, who can use it as decoration or as an actual table. We have always been about being exclusive and different, ever since our founding, and that is what we are doing here.”

(This article by Roberta Naas first appeared on her column on Forbes.com.)